Contact Us

Tel: 0086 755 23248547

Fax: 0086 755 23248547

Skype:simon9969@hotmail.com

Linkman:Simon Gao

Postcode:518106

Web: www. injection-flow.com

E-mail:simon@mpa-tooling.com

Address: Building Yonghui, No. 202, Changchun north Road, Guangming new district, Shenzhen city, China

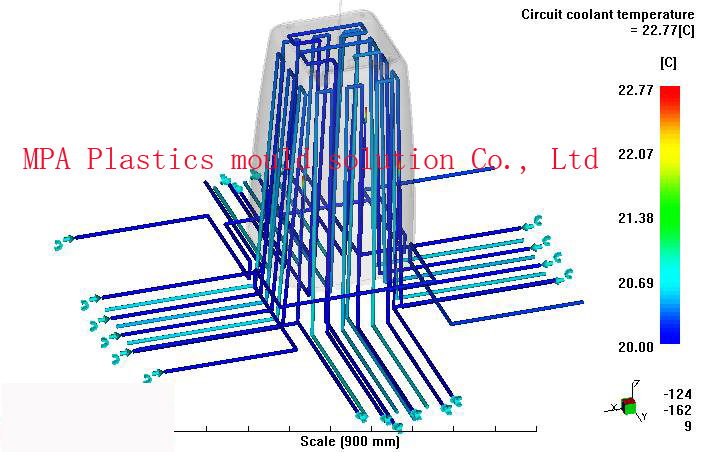

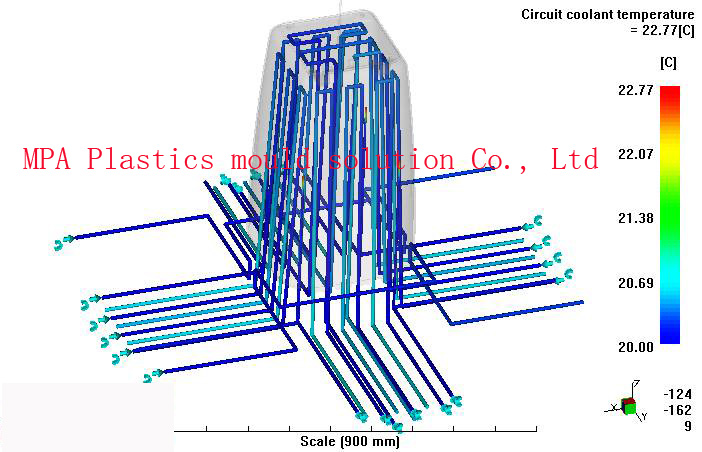

Cooling Analysis

Mold Cooling Simulation to Reduce Cycle Times

Reduce Cycle Times by 20%. ( See stats below )

Mould Cooling simulation allow MPA to optimize mold and cooling circuit design to achieve uniform part cooling, minimize cycle times, minimise part warpage due to cooling factors, and decrease overall manufacturing costs. ie Increase Profit.

Mould Cooling simulation allow MPA to optimize mold and cooling circuit design to achieve uniform part cooling, minimize cycle times, minimise part warpage due to cooling factors, and decrease overall manufacturing costs. ie Increase Profit.

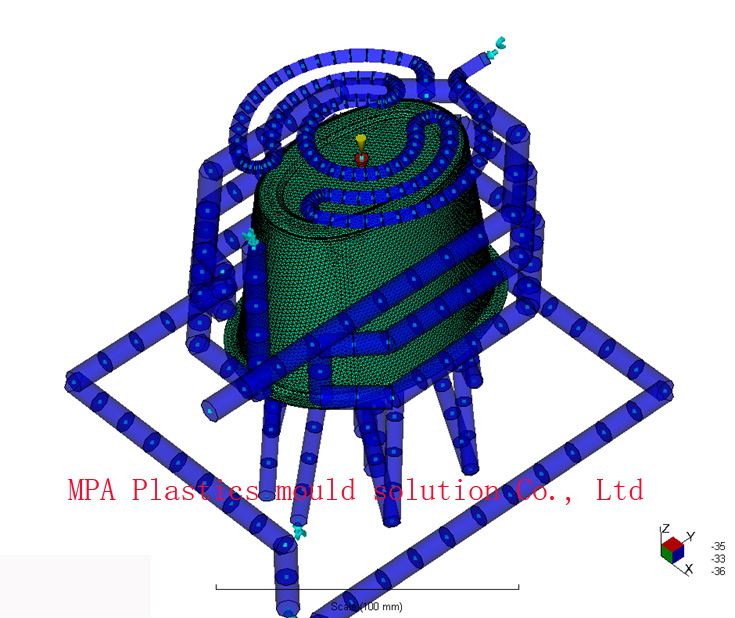

Cooling Channel Design & Optimization

The new industry buzz is "Conformal Cooling" and the concept is synonymous with new rapid tooling technology. Layered mould construction allows cooling channels to break out of straight line constraints and follow the surface of the mould around corners and over irregular profiles.

The new industry buzz is "Conformal Cooling" and the concept is synonymous with new rapid tooling technology. Layered mould construction allows cooling channels to break out of straight line constraints and follow the surface of the mould around corners and over irregular profiles. Typical savings in the order of 20% on cycle time are not uncommon while also using less cooling water and maintaining more even cavity surface temperature profiles.

A number of well placed cooling channels may have slight increase on the tool manufacture cost, but the payback via a shorter cycle time will result in a phenomenal increase in life time profit.

Mold flow MPI/Cool provides tools for modeling mold cooling circuits, inserts, and bases around a part and analyzing the efficiency of the mold's cooling system and helps the tool designer to arrive at an efficient cooling channel layout.

Mold flow MPI/Cool provides tools for modeling mold cooling circuits, inserts, and bases around a part and analyzing the efficiency of the mold's cooling system and helps the tool designer to arrive at an efficient cooling channel layout.A recent study conducted on a thick wall PP moulding helped reduce the cycle time from 215 seconds to 120 seconds with out any compromise on surface finish. The savings were achieved by adding several baffles/fountains to deep pockets and incorporating high conductivity inserts. Contact us and ask about cycle time reduction. Just a couple of seconds reduction in cycle time can save thousands of dollars in machine time over the product life cycle.

Mold Surface Temperature

Mold flow Cooling analysis calculates the mould surface temperature profile based on the temperature of the in-coming polymer melt, the cycle time and location of cooling channels. The position and number of cooling channels are modified to refine the heat exchange characteristics in for maximum efficiency.

Mold flow Cooling analysis calculates the mould surface temperature profile based on the temperature of the in-coming polymer melt, the cycle time and location of cooling channels. The position and number of cooling channels are modified to refine the heat exchange characteristics in for maximum efficiency.

Cooling Analysis Capability:

Optimize part and mold designs to achieve uniform cooling with the minimum cycle time

View the temperature difference between the core and cavity mold surfaces

Minimize unbalanced cooling and residual stress to reduce or eliminate part warpage

Predict temperature for all surfaces within the mold: part, runners, cooling channels, inserts

Predict the required cooling time for the part and cold runner to determine overall cycle time

View the temperature difference between the core and cavity mold surfaces

Minimize unbalanced cooling and residual stress to reduce or eliminate part warpage

Predict temperature for all surfaces within the mold: part, runners, cooling channels, inserts

Predict the required cooling time for the part and cold runner to determine overall cycle time

2005-2015 © Copyright MPA Mold flow analysis Tel:0086 755 23248547 Fax:0086 755 23248547

Sales Representative:simon@mpa-tooling.com