Contact Us

Tel: 0086 755 23248547

Fax: 0086 755 23248547

Skype:simon9969@hotmail.com

Linkman:Simon Gao

Postcode:518106

Web: www. injection-flow.com

E-mail:simon@mpa-tooling.com

Address: Building Yonghui, No. 202, Changchun north Road, Guangming new district, Shenzhen city, China

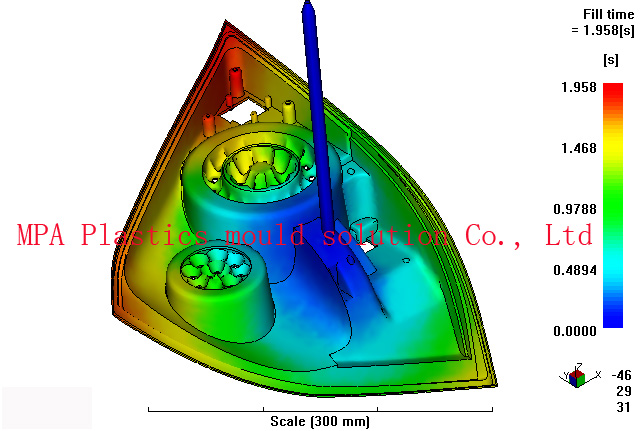

Filling Analysis

Mold flow Flow Analysis "Mpi Complete"

Investigating the mould filling characteristics of an injection mould using mould flow simulation technology highlights potential problems before they actually occur. This enables our engineers to develop a practical solution while the mould design proceeds.

Flow Analysis

Flow analysis simulates the Filling and Packing phases of the injection molding process to predict the flow behavior of thermoplastic melt. Based on results of the study combined with practical experience, MPA is able to increase the certainty of producing acceptable quality parts.

Flow analysis simulates the Filling and Packing phases of the injection molding process to predict the flow behavior of thermoplastic melt. Based on results of the study combined with practical experience, MPA is able to increase the certainty of producing acceptable quality parts.Flow analysis is also a highly effective tool for identify and solving problems with existing molds.

Improvements in part quality are achieved by refining gate points, the position of weld lines, eliminating gas traps, balancing pressure drops and reducing stress levels.

The holding phase simulates pressurisation of the injection mold cavity after the initial dose of polymer melt has filled the cavity. During the packing phase the cavity is bought up to pressure by forcing more melt through the gate until the gate freezes off when the pressure is released. Results calculated during the packing phase include a refined clamp force prediction, volumetric shrinkage, freeze times and sink marks.

3D Simulation

3D Flow is a high-end flow simulation tool that allows MPA Engineers to understand how plastic flows in thick-walled or chunky parts. The 3D flow analysis directly analyzes a volume mesh (4-node, tetrahedral mesh) of a solid model.

3D Flow is a high-end flow simulation tool that allows MPA Engineers to understand how plastic flows in thick-walled or chunky parts. The 3D flow analysis directly analyzes a volume mesh (4-node, tetrahedral mesh) of a solid model.

The simulation shows results through the entire part thickness, predicts jetting and is excellent for Gas Injection simulation.

Filling Analysis Capability:

Predict and visualize the flow front progression to see how the mold fills.

Predict and visualize the flow front progression to see how the mold fills. Determine injection pressure and clamp force requirements.

Optimize part wall thickness to achieve uniform filling, minimize cycle time, and reduce part cost.

Predict weld line locations and either move, minimize, or eliminate them.

Identify potential air traps and determine locations for proper mold venting.

Optimize process conditions such as injection time, injection velocity profile, melt temperature, packing pressure, packing time, and cycle time.

Determine areas of high volumetric shrinkage that could cause part warpage problems.

Determine gate freeze time.

Simulate the Synventive Molding Solutions Dynamic Feed system, a hot runner system which provides independent melt pressure-based process control for up to 32 nozzles in a single mold.

Simulate part insert over molding and two-shot sequential over molding processes.

2005-2015 © Copyright MPA Mold flow analysis Tel:0086 755 23248547 Fax:0086 755 23248547

Sales Representative:simon@mpa-tooling.com