Contact Us

Tel: 0086 755 23248547

Fax: 0086 755 23248547

Skype:simon9969@hotmail.com

Linkman:Simon Gao

Postcode:518106

Web: www. injection-flow.com

E-mail:simon@mpa-tooling.com

Address: Building Yonghui, No. 202, Changchun north Road, Guangming new district, Shenzhen city, China

Automotive

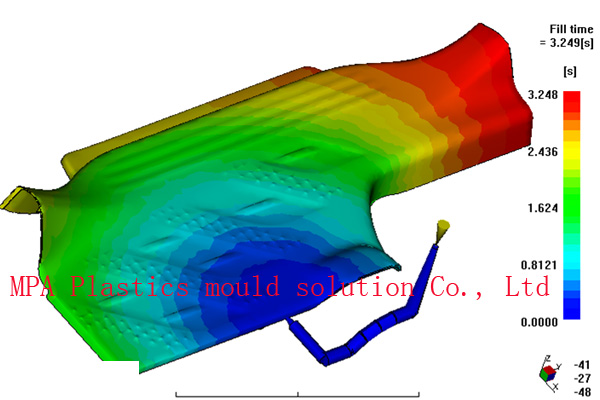

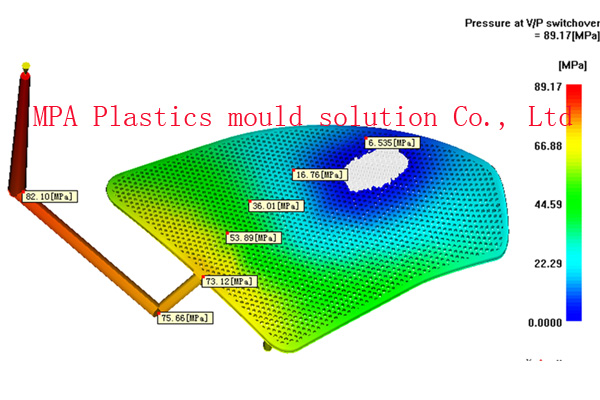

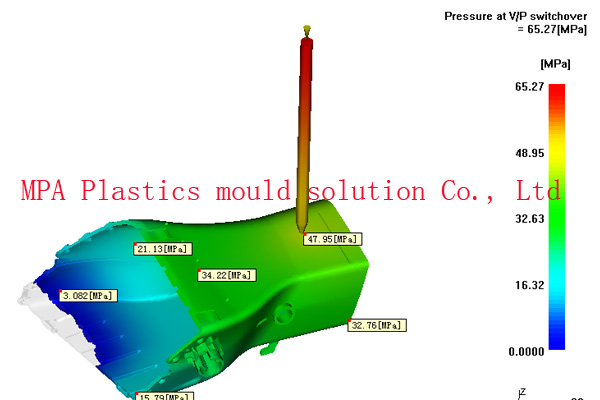

Plastics Analysis Solutions for Automotive Applications

MPA have analyzed hundreds of automotive mouldings over the years including exterior fascias, interior door, luggage, instrument panels and mouldings for under bonnet applications.

Automotive production techniques are often at the forefront of technological development and MPA has been active in aiding the development of many advanced systems.

Automotive production techniques are often at the forefront of technological development and MPA has been active in aiding the development of many advanced systems.

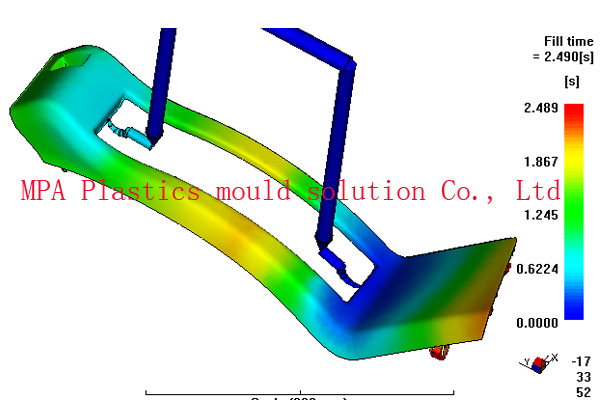

Bumper systems

Polypropylene bumper systems are a good case in point, over the last 10 to 15 years moving from painted .

multi feed tools to large film gates and now sequential feed hot runner systems .

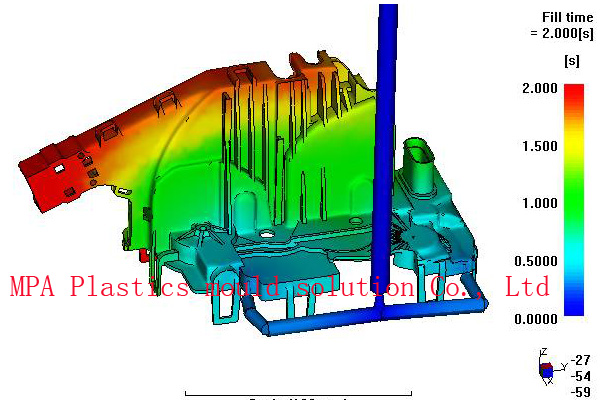

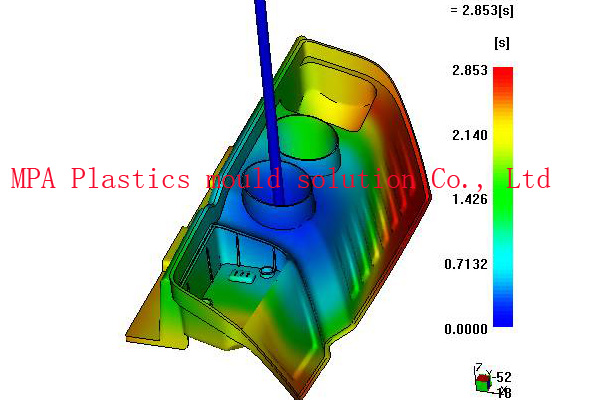

Interior Panels

The use of sequential injection has also seen a reduction in the requirement to paint

and now the addition of complex integral detail such as speaker grilles and air bag doors is

common place. Some interior panels now incorporate thick feel gas injected door pockets

and thin speaker grille sections eliminating the need for several mouldings.

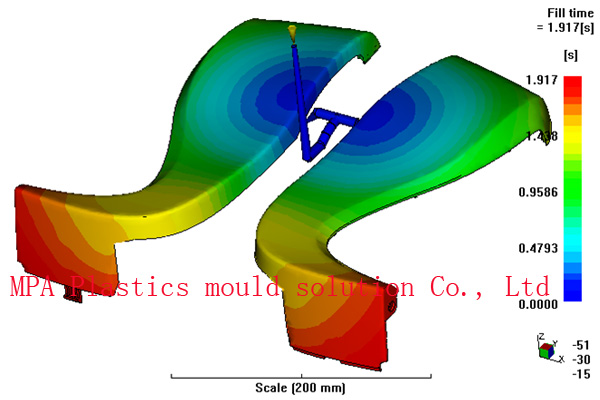

Under Body Mouldings

2005-2015 © Copyright MPA Mold flow analysis Tel:0086 755 23248547 Fax:0086 755 23248547

Sales Representative:simon@mpa-tooling.com