Contact Us

Tel: 0086 755 23248547

Fax: 0086 755 23248547

Skype:simon9969@hotmail.com

Linkman:Simon Gao

Postcode:518106

Web: www. injection-flow.com

E-mail:simon@mpa-tooling.com

Address: Building Yonghui, No. 202, Changchun north Road, Guangming new district, Shenzhen city, China

Warpage Analysis

Mold flow Shrinkage & Warpage Analysis

Warpage occurs when there are variations of internal stresses in the material caused by a variation in shrinkage. Warped parts may not be functional or visually acceptable.

1, Non-uniform cooling. Temperature differences from one side of the mold to the other can lead to layers freezing and shrinking at different times and generating internal stresses.

2, Inconsistent shrinkage. Resulting from:

A, Material variations such as property variations, Fillers, varying moisture content, inconsistent melt and pigmentation;

B, Process conditions variations such as inconsistent packing and varying mold and melt temperatures;

C, Machine variations such as a damaged check ring and unstable controller.

1, Non-uniform cooling. Temperature differences from one side of the mold to the other can lead to layers freezing and shrinking at different times and generating internal stresses.

2, Inconsistent shrinkage. Resulting from:

A, Material variations such as property variations, Fillers, varying moisture content, inconsistent melt and pigmentation;

B, Process conditions variations such as inconsistent packing and varying mold and melt temperatures;

C, Machine variations such as a damaged check ring and unstable controller.

Part Shrinkage

MPI/Warp calculates shrinkage and warpage in injection molded plastic parts and predicts where deformations will occur.

MPI/Warp calculates shrinkage and warpage in injection molded plastic parts and predicts where deformations will occur. Results allow MPA to optimize design, material, and processing parameters to control part warpage before the mold is built.

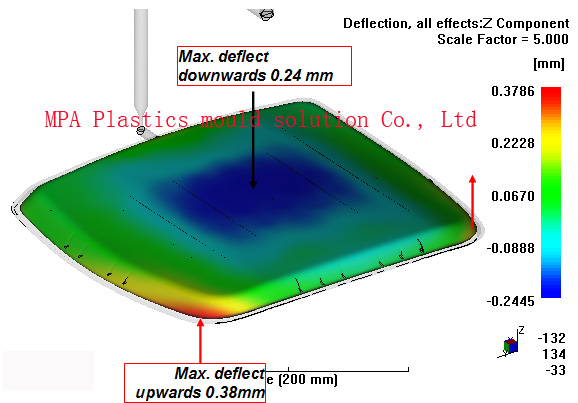

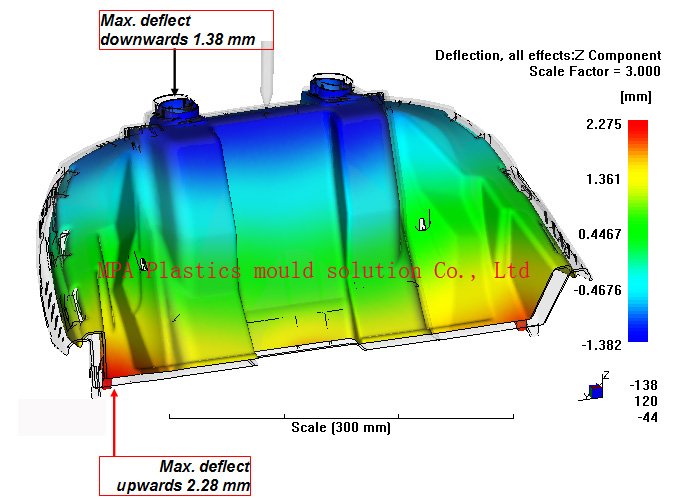

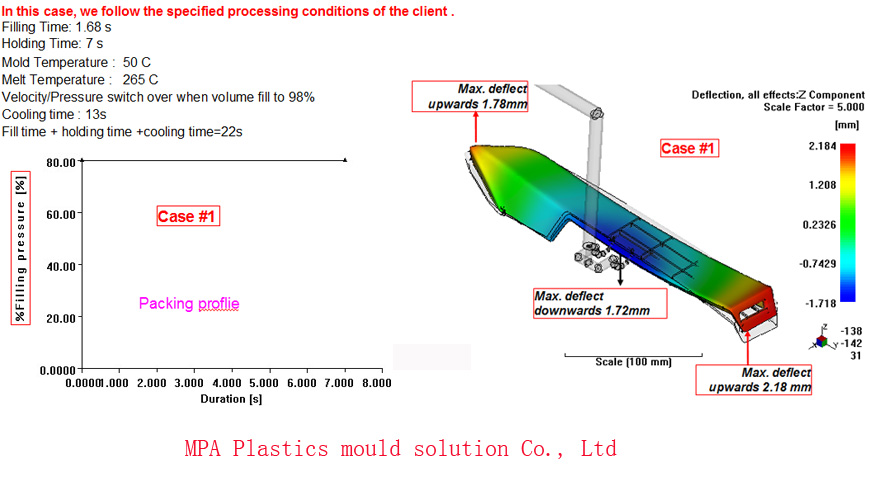

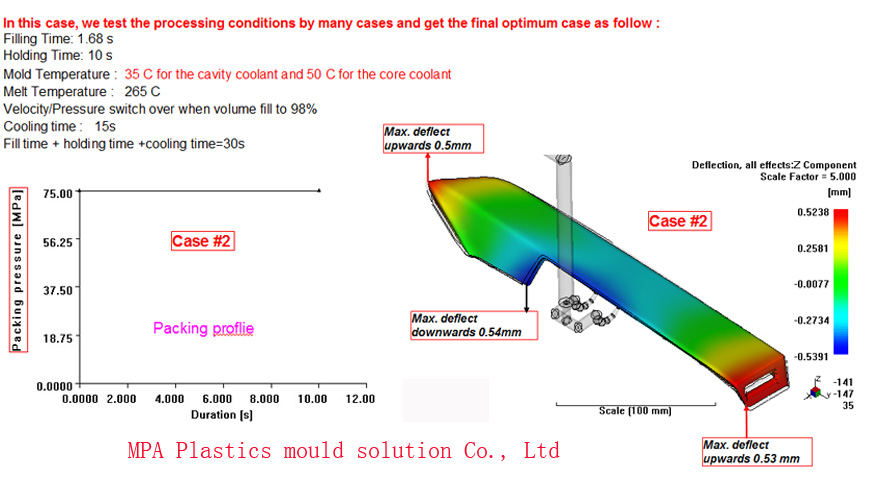

Deflection Results

With MPI/Warp, even the most demanding application that requires high dimensional stability, excellent visual appearance, and accurate fit with mating components can be produced to quality, time, and budgetary specifications.

With MPI/Warp, even the most demanding application that requires high dimensional stability, excellent visual appearance, and accurate fit with mating components can be produced to quality, time, and budgetary specifications.In mold compensation is also possible. By exporting a inverse model from Mold flow toolmakers are able to compensate for unavoidable distortion in the mold.

Shrinkage & Warpage Analysis Capability:

Evaluate final part shape before machining the mold

Evaluate both single cavity and multi-cavity molds

Scale shrinkage and warpage results for better visualization of deformation

Query any two points to determine any dimensional change between the two

Constrain the part on a plane for better measurement of deflection

Separate total displacement into X-, Y-, and Z-axis displacements to show only the deflection in each direction

Show shrinkage and warpage as a visible displacement plot or as a color contour or shaded plot

Export warp geometry in the STL format to use as a reference when sizing the mold

Export warp mesh model for an iterative warpage analysis

Evaluate both single cavity and multi-cavity molds

Scale shrinkage and warpage results for better visualization of deformation

Query any two points to determine any dimensional change between the two

Constrain the part on a plane for better measurement of deflection

Separate total displacement into X-, Y-, and Z-axis displacements to show only the deflection in each direction

Show shrinkage and warpage as a visible displacement plot or as a color contour or shaded plot

Export warp geometry in the STL format to use as a reference when sizing the mold

Export warp mesh model for an iterative warpage analysis

|

|

2005-2015 © Copyright MPA Mold flow analysis Tel:0086 755 23248547 Fax:0086 755 23248547

Sales Representative:simon@mpa-tooling.com